Kenaf Bioplastic: A Sustainable Solution for a Plastic-Free Future

Plastic pollution has become a global environmental crisis, prompting the search for sustainable alternatives to traditional petroleum-based plastics. Kenaf bioplastic, derived from the versatile kenaf plant, offers a promising solution. This article explores the potential of kenaf bioplastic as an eco-friendly alternative, highlighting its benefits, applications, and contribution to a plastic-free future.

The Rise of Kenaf

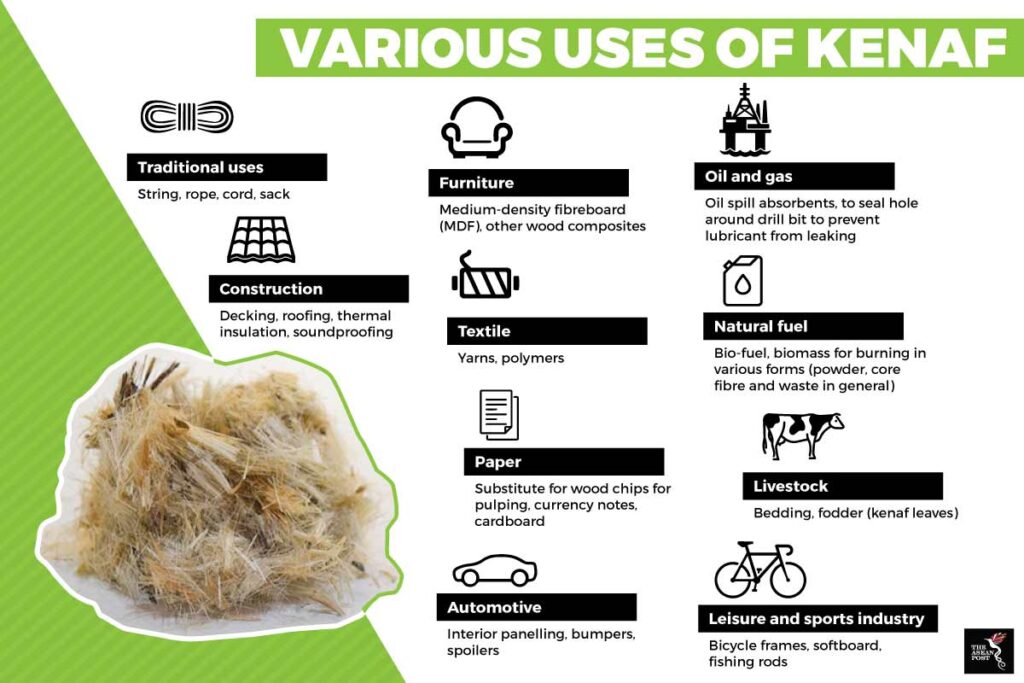

Kenaf (Hibiscus cannabinus) is a member of the hibiscus family and is native to West Africa. It is a warm-season annual plant that thrives in tropical and subtropical regions. Its remarkable growth rate, reaching up to 4-5 meters in just a few months, makes it a highly sustainable and renewable resource. Its utilization extends beyond traditional applications like fiber production and paper-making, as kenaf is now gaining recognition for its potential in creating lightweight materials.

understanding kenaf bioplastic

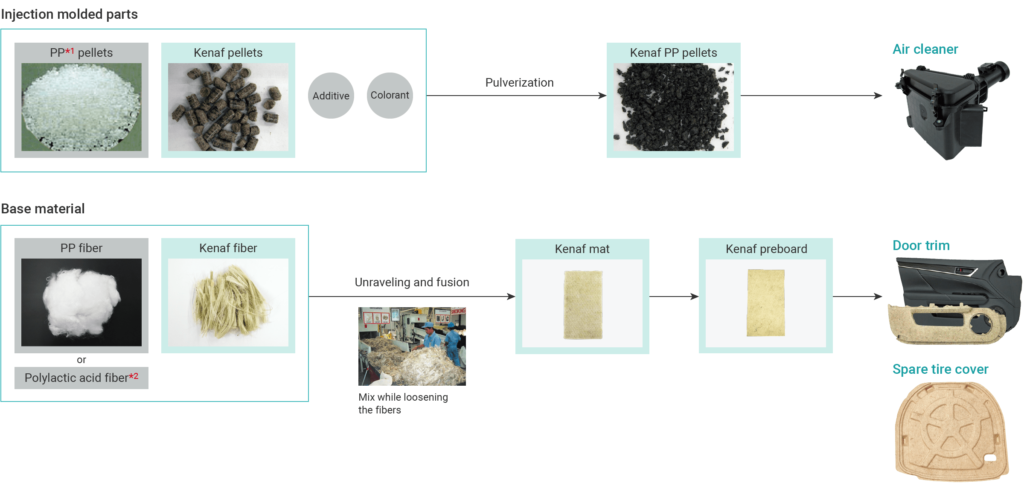

Kenaf bioplastic is a type of biodegradable plastic derived from the fibers of the kenaf plant (Hibiscus cannabinus). Kenaf is an annual crop known for its rapid growth, sustainability, and low environmental impact. The plant’s fibers can be processed and transformed into a range of bioplastic products, reducing reliance on fossil fuels and minimizing the ecological footprint associated with traditional plastic production.

Automotive and Aerospace Industries

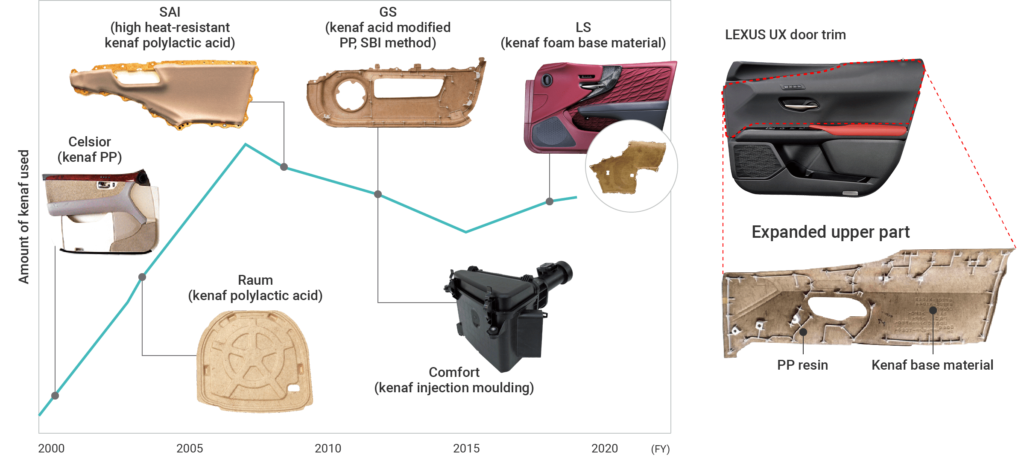

The automotive and aerospace sectors are constantly seeking ways to reduce weight without compromising strength and safety. Kenaf bioplastic, when combined with other materials such as resins, can create composite materials that are significantly lighter than traditional alternatives. These kenaf-based composites offer excellent strength-to-weight ratios, contributing to improved fuel efficiency, reduced emissions, and enhanced performance in vehicles and aircraft.

Environmental Benefits of Kenaf Bioplastic

Renewable and Sustainable:

Kenaf is a fast-growing plant that requires minimal resources and has a short harvesting cycle. It can be cultivated without the need for excessive water, pesticides, or fertilizers, making it a renewable and sustainable source of raw material for bioplastic production.

Reduced Carbon Footprint

The cultivation of kenaf plants helps absorb carbon dioxide from the atmosphere, acting as a natural carbon sink. As kenaf bioplastic replaces petroleum-based plastics, it helps reduce greenhouse gas emissions and mitigate climate change.

Biodegradability

Unlike traditional plastics that persist in the environment for hundreds of years, kenaf bioplastic is biodegradable. It can break down naturally over time, reducing the accumulation of plastic waste in landfills and ecosystems.

applications of kenaf bioplastic

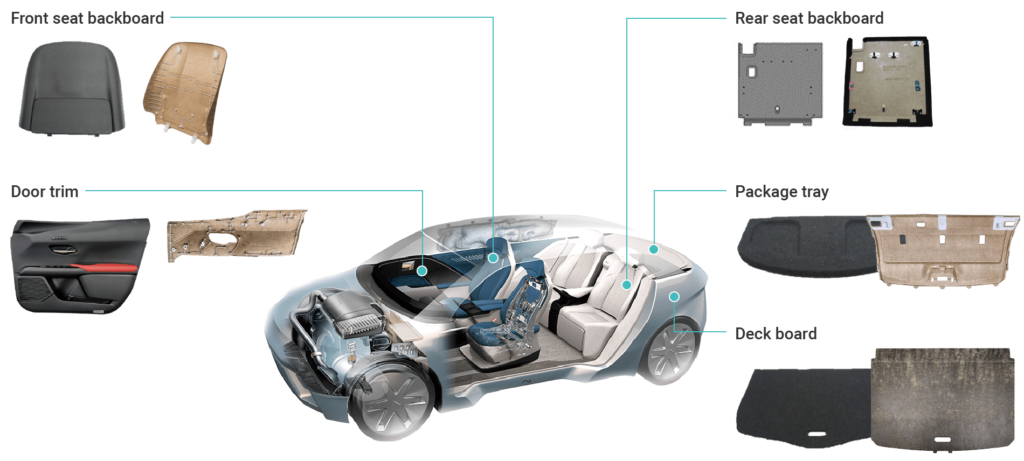

Interior Components

Kenaf bioplastic can replace traditional plastic or composite materials in interior components such as door panels, dashboard trims, and seat backs. These lightweight and sustainable alternatives contribute to fuel efficiency, reduce emissions, and enhance the overall interior experience.

Exterior Parts

Kenaf bioplastic-based body panels, fenders, and bumpers offer weight reduction without compromising structural integrity. These components contribute to improved aerodynamics, reduced fuel consumption, and enhanced vehicle safety.

Spacecraft Interiors

Kenaf bioplastic can be utilized in space missions for lightweight and sustainable interior components. From instrument panels to storage compartments, kenaf bioplastic provides a viable alternative to conventional materials, reducing weight and resource consumption during space travel.

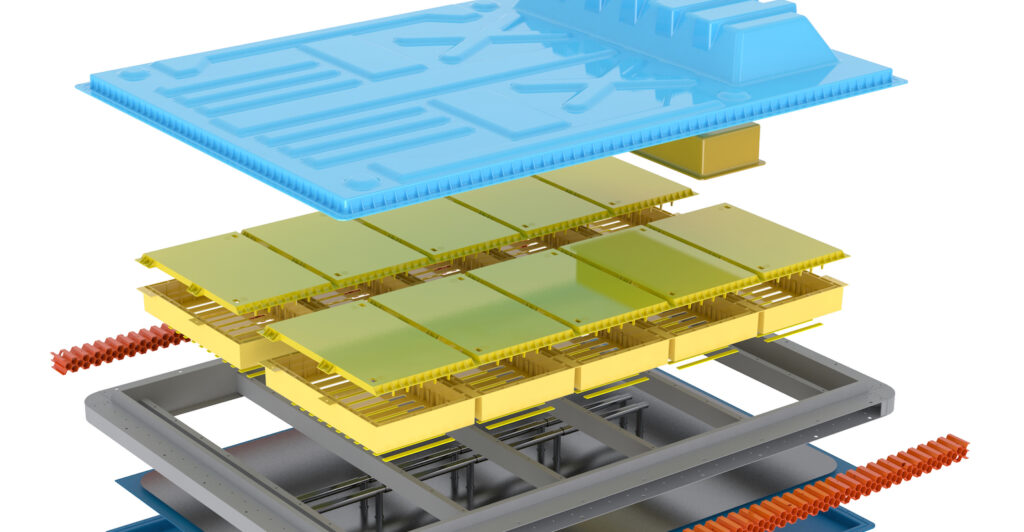

Battery Casings

With the growing demand for electric vehicles, kenaf bioplastic can be used for battery casings. Its insulation properties, thermal stability, and lightweight nature make it suitable for protecting and housing high-performance batteries in electric and hybrid vehicles.